Climate change demands urgent action, and Direct Air Capture Technology stands at the forefront of carbon removal solutions. While mechanical systems have dominated headlines, biological carbon sequestration through microalgae presents a compelling alternative that’s reshaping atmospheric CO2 removal. This analysis explores why nature-based solutions outpace their mechanical counterparts in efficiency, scalability, and environmental impact.

As carbon dioxide removal companies worldwide race to develop viable climate solutions, understanding the differences between mechanical and biological approaches is crucial for stakeholders making infrastructure and sustainability decisions in 2025 and beyond.

Key Takeaways

- Biological systems using microalgae capture CO2 at significantly lower energy costs compared to mechanical direct air capture, reducing operational expenses by up to 70% while producing valuable bio-products like spirulina and omega-3 oils.

- Mechanical DAC systems require 1.5-2.5 MWh per ton of CO2 captured, whereas microalgae-based solutions operate at ambient temperatures with minimal energy input, making them more sustainable and economically viable.

- Scalability and urban infrastructure integration favor biological systems, which seamlessly incorporate into building facades and existing structures without the massive industrial footprint required by mechanical systems.

Understanding Direct Air Capture CO2: The Two Pathways

Direct Air Capture CO2 technology removes carbon dioxide directly from ambient air through two fundamentally different approaches: mechanical systems using chemical processes and energy-intensive equipment, and biological systems harnessing photosynthetic organisms like microalgae. Each pathway addresses the same challenge—reducing atmospheric CO2—but employs vastly different methodologies with distinct implications for efficiency, scalability, and sustainability.

Mechanical DAC employs large industrial fans pushing massive volumes of air through chemical filters containing sorbents like potassium hydroxide or amine-based solutions. These chemicals bind with CO2 molecules, which are then released through heating processes reaching 80-120°C for storage or utilization. The process demands substantial infrastructure including fan arrays, chemical processing equipment, heat exchangers, and storage facilities. Research from the International Energy Agency indicates current mechanical facilities capture approximately 10,000 tons of CO2 annually per installation, requiring continuous energy input and industrial-scale operations to maintain economic viability.

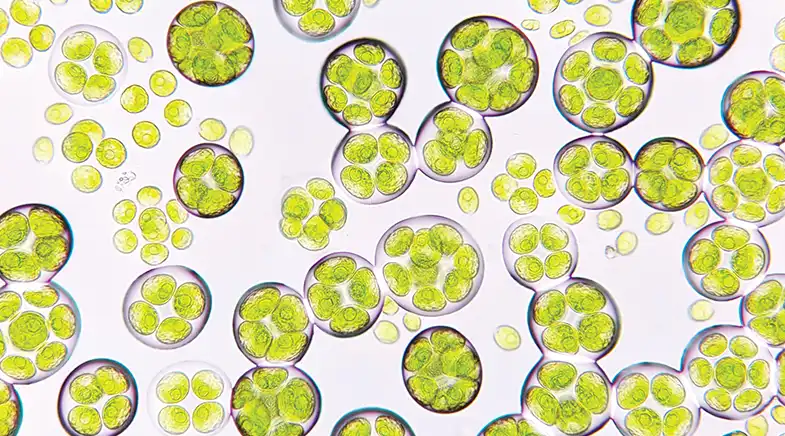

Biological Carbon Sequestration takes a nature-based approach, accelerating natural photosynthesis processes that have regulated Earth’s atmosphere for billions of years. Microalgae consume CO2 at rates 10-50 times faster than terrestrial plants, converting atmospheric carbon into biomass through photosynthesis. This biomass becomes feedstock for high-value bioproducts including nutritional supplements, biofuels, pharmaceuticals, and industrial compounds. Carbelim’s microalgae photobioreactor technology optimizes these natural processes for urban deployment, creating economic value from captured carbon while eliminating the need for geological storage.

The fundamental philosophical difference proves critical: mechanical systems fight against thermodynamic principles, requiring massive energy inputs to overcome entropy and concentrate dilute atmospheric CO2. Biological systems work with nature’s proven carbon cycle, using solar energy to drive photosynthesis just as plants have done for millennia—but at dramatically accelerated rates through optimized cultivation conditions. This distinction becomes pivotal when evaluating real-world performance, long-term cost-effectiveness, and comprehensive environmental impact across the full technology lifecycle.

The Energy Economics: Why Biological Systems Win

Energy consumption represents the critical weakness of mechanical CO2 Capture Technology. Solid sorbent DAC systems require approximately 1.5-2.0 megawatt-hours per ton of CO2 captured, with liquid solvent systems demanding up to 2.5 MWh. When powered by fossil fuels, the carbon footprint undermines the entire operation.

Consider the scale: capturing one million tons of CO2 annually requires 1.5-2.5 million MWh—equivalent to powering 140,000-230,000 homes yearly. Without renewable energy, these systems relocate rather than reduce emissions.

Biological systems operate fundamentally differently. Microalgae perform photosynthesis at ambient temperatures, requiring only sunlight as primary energy. Supplementary energy for circulation and harvesting totals less than 0.3 MWh per ton—an 80-85% reduction. According to Nature Communications, microalgae cultivation achieves net negative emissions even accounting for operational energy.

With industrial electricity at $0.07-0.12 per kWh, mechanical DAC’s energy costs alone range from $105-300 per ton. Biological systems reduce this to $20-35 per ton, creating immediate advantages that compound over facility lifetimes. Combined with bioproduct revenue, biological systems approach carbon-negative economics.

Industrial CCUS solutions demonstrate these advantages in real applications, achieving remarkable efficiency while generating additional revenue unavailable to mechanical counterparts. Temperature management widens the gap further—mechanical DAC requires heating to 80-120°C for regeneration, consuming 70% of total energy. Microalgae systems operate within ambient ranges, eliminating expensive heating infrastructure.

Scalability and Urban Integration: Nature’s Competitive Edge

The critical question isn’t whether we can build mechanical DAC facilities—we can—but whether we can scale them sufficiently to address climate change meaningfully. Current mechanical installations occupy industrial footprints spanning several football fields, with facilities requiring 5-10 hectares of land for every 1,000 tons of daily capture capacity. Scaling to climate-significant removal would require thousands of such facilities, each demanding substantial land, water, and infrastructure resources. For context, removing just 1% of current annual global CO2 emissions (approximately 400 million tons) would require 40,000 mechanical DAC facilities of current design—an implausible deployment scenario.

Biological carbon sequestration offers radical scalability advantages through vertical integration and building incorporation. Photobioreactors integrate vertically on building facades, horizontally across rooftops, and into existing structures without consuming additional land. The Carbelim Biomimetic Facade (CBF™) exemplifies this approach, transforming building exteriors into active carbon capture surfaces. A 20-story commercial building with 5,000 square meters of suitable facade area can capture 50-100 tons of CO2 annually while providing thermal insulation, reducing building cooling loads by 15-25%, and improving local air quality—multifunctional benefits mechanical DAC cannot deliver.

Urban environments particularly benefit from this integration model. Consider a city like Dubai deploying biological carbon capture across 10,000 buildings—this distributed network could capture 500,000 to 1 million tons of CO2 annually while enhancing building performance and urban aesthetics. Mechanical DAC installations lack this multifunctionality and space efficiency, requiring dedicated industrial zones far from population centers.

Modular deployment represents another decisive advantage. Photobioreactors scale incrementally—adding panels or units increases capacity linearly without requiring complete system redesigns or minimum viable scales. A building owner can start with 100 square meters of facade coverage and expand as budget permits or as carbon credits make projects more attractive. Mechanical DAC facilities, conversely, require minimum viable scales for economic operation, typically 10,000+ tons annually, creating high capital barriers ($5-10 million minimum) and inflexible deployment options that exclude smaller organizations from participation.

Installation timelines dramatically favor biological systems. Mechanical DAC facilities require 2-4 years from planning through permitting, construction, and commissioning to full operation. Biological systems deploy in weeks or months—a building facade installation can be operational within 3-6 months from decision to carbon capture. For organizations targeting 2030 carbon neutrality with only six years remaining, this timeline difference proves decisive. Early action with biological systems delivers cumulative carbon removal that mechanical systems’ longer deployment cycles cannot match.

The carbon capture and utilization model inherent to biological systems creates circular economies that mechanical approaches fundamentally cannot replicate. Rather than requiring expensive geological storage or finding buyers for captured CO2 (a limited market), biological systems transform atmospheric waste into valuable products through natural processes. This eliminates the “what do we do with the CO2?” problem that challenges mechanical DAC economics and creates additional barriers to widespread adoption.

Product Value Creation: From Cost Center to Revenue Generator

Biological systems revolutionize carbon capture economics by transforming expenses into assets. Mechanical Direct Air Capture Technology faces an existential challenge—captured CO2 must be stored (incurring costs) or sold (into limited markets). Economics rarely close without substantial subsidies.

Biological carbon sequestration changes this calculation. Captured CO2 becomes microalgae biomass rich in proteins, lipids, and pigments. This creates multiple revenue streams:

- Nutritional Products: Spirulina commands $20-40 per kilogram, generating $2-4 million annually per 100 tons of biomass

- Biofuels and Bio-oils: Algae lipids convert to biodiesel and sustainable aviation fuel, with demand projected to reach 450 billion liters by 2050

- Pigments and Nutraceuticals: Compounds like phycocyanin sell for $500-5,000 per kilogram in pharmaceutical applications

- Animal Feed: Aquaculture industries increasingly adopt algae protein, creating stable demand in a $3+ billion market

- Bioplastics: Algae biomass serves as renewable feedstock for biodegradable plastics

Revenue diversification insulates biological systems from carbon market volatility. Even if carbon credits decline, product sales sustain operations—flexibility mechanical DAC completely lacks. The circular economy integration proves equally valuable, exemplifying cradle-to-cradle design where “waste” carbon becomes valuable biomass, then commercial products.

Life Cycle Assessment: The Full Environmental Picture

Carbon dioxide removal companies must account for complete environmental impacts beyond CO2 capture rates. Life cycle assessments reveal significant disparities between approaches.

Mechanical DAC systems embody substantial carbon debt. Manufacturing steel, concrete, chemical sorbents, and electronics generates 200-400 tons of CO2 per ton of daily capacity. A 1,000-ton daily facility creates 200,000-400,000 tons of carbon debt before capturing anything, with payback periods extending 5-15 years.

Chemical sorbent production adds ongoing emissions. Amine-based sorbents degrade, requiring replacement. Each ton manufactured generates 3-5 tons of CO2 equivalent. Water consumption presents another concern—mechanical DAC requires 1-5 tons per ton of CO2 captured, creating sustainability conflicts in water-stressed regions.

Biological systems demonstrate superior performance. Photobioreactor construction uses glass, aluminum, and plastics with lower embodied carbon. Equivalent capacity carries only 40-80 tons of carbon debt, achieving net-positive removal within 1-2 years.

Microalgae cultivation requires water, but closed-loop systems recycle 90-95%, reducing consumption to 0.2-0.5 tons per ton of CO2. Systems can utilize brackish or wastewater, eliminating competition for potable water. Thealgae-based air purifier applications demonstrate these co-benefits in urban settings, providing oxygen production and temperature moderation alongside carbon capture.

Operational Performance: Resilience and Maintenance

Real-world reliability separates theoretical advantages from practical superiority. CO2 Capture Technology must function across varying conditions and inevitable equipment challenges.

Mechanical DAC suffers from complexity. Thousands of moving parts create numerous failure points, with systems averaging 60-75% uptime and 25-40% downtime for maintenance. Chemical sorbents perform optimally within narrow temperature ranges, with performance compromised by temperature swings in desert or winter conditions.

Biological systems demonstrate remarkable resilience. Microalgae adapt to varying conditions, continuing to function across wider temperature, light, and nutrient ranges. While optimal growth occurs within preferred parameters, systems don’t collapse during suboptimal conditions—efficiency merely reduces until improvements.

Maintenance requirements diverge dramatically. Photobioreactor maintenance involves cleaning surfaces, monitoring culture health, and harvesting—tasks requiring less specialized labor than mechanical repairs. A facility technician manages biological systems; mechanical DAC demands specialized engineers.

Self-repair capabilities give biological systems additional advantages. Contamination in mechanical systems requires shutdowns and recharging. Biological systems outgrow contaminants through culture management, with microalgae populations doubling every 1-3 days under optimal conditions.

Distributed biological systems like Direct Air Capture solutions integrated across multiple buildings ensure partial functionality even when individual systems face issues, maintaining carbon removal during recovery periods.

Cost Analysis: Economic Viability

Economic viability determines technology adoption. Current cost structures reveal significant disparities, with future projections compounding these advantages.

Mechanical DAC capital costs range from $500-1,000 per ton of annual capacity. A one million ton facility requires $500 million to $1 billion, excluding land, grid connection, and infrastructure. Total costs often exceed $1.2-1.5 billion.

Biological systems cost $200-400 per ton annually—a 50-75% reduction. Modular deployment permits phased investment, with early installations generating revenue to fund expansion. A million-ton biological network requires $200-400 million in phased investment.

Operating expenses perpetuate disparities. Mechanical DAC costs $200-400 per ton captured, driven by energy and chemicals. Biological systems operate at $80-150 per ton. Including bioproduct revenue, biological systems achieve net costs of $40-80 per ton, with optimized systems approaching profitability.

At current $50 per ton carbon credits, mechanical DAC loses $150-350 per ton. Biological systems profit $20-40 per ton with product revenues—a $170-390 per ton competitive advantage. Future scenarios maintain this gap, as both technologies benefit from similar learning curves while biological systems gain from biotechnology advances.

Conclusion: The Path Forward for Carbon Removal

The evidence overwhelmingly supports biological carbon sequestration as superior Direct Air Capture Technology for most applications. Energy efficiency advantages, product value creation, superior lifecycle impacts, and favorable economics create compelling benefits that compound over time.

This doesn’t mean mechanical DAC lacks value—specific applications where biomass production proves impractical may favor mechanical approaches. However, for urban integration, distributed deployment, and economically sustainable removal at climate-relevant scales, biological systems lead decisively.

Organizations evaluating carbon removal strategies should prioritize biological approaches, particularly microalgae-based solutions delivering proven performance, revenue generation, and rapid deployment. As we race against climate tipping points, choosing effective tools matters enormously. Direct Air Capture CO2 through biological carbon sequestration represents our best hope for affordable, scalable atmospheric carbon removal while creating economic value and supporting sustainable development.

Ready to transform your building into a carbon-negative asset? Contact Carbelim to discuss customized solutions aligning environmental impact with economic return.

What is Direct Air Capture Technology and how does it work?

Direct Air Capture Technology removes CO2 from ambient air using mechanical systems with chemical sorbents or biological systems using microalgae. Biological systems harness photosynthesis to convert atmospheric carbon into biomass, offering lower energy costs.

How does biological carbon sequestration compare to mechanical DAC in cost?

Biological sequestration costs $80-150 per ton versus $200-400 for mechanical systems. With bioproduct revenue, biological systems achieve net costs of $40-80 per ton, while mechanical systems depend entirely on carbon credits.

Can microalgae-based carbon capture systems scale to climate-significant levels?

Yes, microalgae systems scale through distributed urban deployment via PureAir Network™. They integrate into building facades and infrastructure across thousands of locations, achieving massive CO2 removal without land-use conflicts limiting mechanical systems.

What products can be generated from captured CO2 using biological systems?

Biological capture produces spirulina proteins, biofuel lipids, omega-3 oils, pharmaceutical pigments, aquaculture feed supplements, and bioplastic feedstock. These products generate $2-4 million annually per 100 tons of biomass, offsetting capture costs.

How much energy does Direct Air Capture Technology require?

Mechanical DAC requires 1.5-2.5 megawatt-hours per ton of CO2, primarily for heating and regeneration. Biological systems using microalgae need less than 0.3 MWh per ton—an 80-85% energy reduction using ambient-temperature photosynthesis.

Which industries benefit most from biological carbon capture solutions?

Real estate developers, urban planners, corporate campuses, and municipalities benefit most. Building-integrated systems provide carbon removal, thermal insulation, and improved air quality while generating valuable biomass products offsetting operational costs.

What are the maintenance requirements for microalgae-based carbon capture?

Microalgae systems require culture monitoring, surface cleaning, nutrient management, and harvesting—manageable by facility technicians. Systems achieve 85-95% uptime with self-repair through rapid algae growth, versus mechanical DAC’s 60-75% uptime requiring specialized maintenance.

How do climate conditions affect biological versus mechanical carbon capture systems?

Biological systems demonstrate greater resilience across temperature ranges. Microalgae continue functioning in varied conditions, while mechanical systems rely on chemical sorbents performing optimally only within narrow parameters, with efficiency compromised by extreme temperatures.

What carbon removal capacity can building-integrated biological systems achieve?

Building facade systems achieve 1-2 tons of CO2 removal per 100 square meters annually. A commercial building with 5,000 square meters of facade captures 50-100 tons yearly while generating biomass and improving thermal performance.

Are there government incentives available for Direct Air Capture projects?

Incentives include U.S. 45Q tax credits ($180/ton), California and European carbon markets, building code bonuses, and renewable fuel standards. Carbelim helps navigate these programs, with biological systems qualifying for additional bioeconomy incentives.